Barcode Units can be found in various types, including general-purpose laser and inkjet printers. Then you will find units that support multiple symbologies. They are called Thermal bar signal name printers. General-purpose laser and inkjet units can not immediately printing barcodes Thermal Transfer Overprinters.

That’s because these fundamental units do not support bar signal symbologies and are therefore enhanced to complete so. They need to be developed to guide bar development, which might entail supplement of more characteristics and fonts.

Barcode units employ two significant making practices, namely Direct Thermal and Thermal Transfer. Both practices basically include exactly the same method to printing bar codes with big difference in the usage of ribbon. They utilize a print-head that applies heat to a floor that’s pre-marked.

Heated bow is employed to create long-lasting pictures in Thermal Move making, while Direct Thermal does not use bow and alternatively designs the image entirely on the label. In Thermal Move making, a big quantity of components may be used. That typically helps in producing resilient pictures over a long period of time. Direct Thermal, on the other give, helps for making put-away labels, receipts and other such little variety.

Ultimately, barcode units can printing on labels which are created specifically for the purpose. But, the units will also be effective at making on fabrics like polyester. We have units etching away designs on headbands and also artificial materials.

Very despite popular perception, barcodes aren’t only black. Barcode units can printing in a variety of colors, but black is typically chosen just because a mild shade may possibly end up with insufficient comparison between the bars leading to unreadable barcodes.

You can find two main factors in bar signal making for little companies, first the units the application works together and secondly the printing quality. Many software can send printing commands to Windows based units, including ink plane, laser and dot matrix. Needless to say they’re also compatible with popular thermal printers. But what is the big difference? And what works the very best?

Inkjet units are inexpensive and adequate for some employs, although not bar signal printing. Scanners need a high quality level and these kind of units can not give consistent quality.

Laser units can work for bar signal making, but may not be ideal for bulk production. Typically, laser units printing bar codes on frequent tag types like Avery, which may be bought anywhere. Which means this is an excellent choice for a tiny company that only needs a limited quantity of stickers or it is an excellent decision to make use of as a straight back up, like for making replacement stickers.

Dot matrix units are impact type units and continue to be employed for things such as types with multiple copies. But they may also be employed for jobs that do perhaps not involve shade and do not involve high quality. In certain uncommon cases they are used to printing receipts that have bar codes on them, but the standard isn’t dependable.

Direct thermal units make use of a printing check out create heat that triggers a chemical response in particularly made report that converts the report black. Direct thermal units are often more affordable, nevertheless they produce labels that will become illegible if confronted with heat, direct sunlight, or chemical vapors.

Barcode units involve typical washing of the bow and the printing head. Specks of dust could cause distortion of the bar codes. The components of those units applying ANSI software need to be consistently examined to be able to check for process malfunctions.

Thermal move units also use heat, but rather of working entirely on the report, heat touches a waxy or resin material on a bow that works over the name or tag material. Heat transfers ink from the bow to the paper. Thermal Move involves the usage of a hot bow to create long-lasting pictures of knowledge onto a brand and/or tag, whereas Direct Thermal process designs the image entirely on the label/tag.

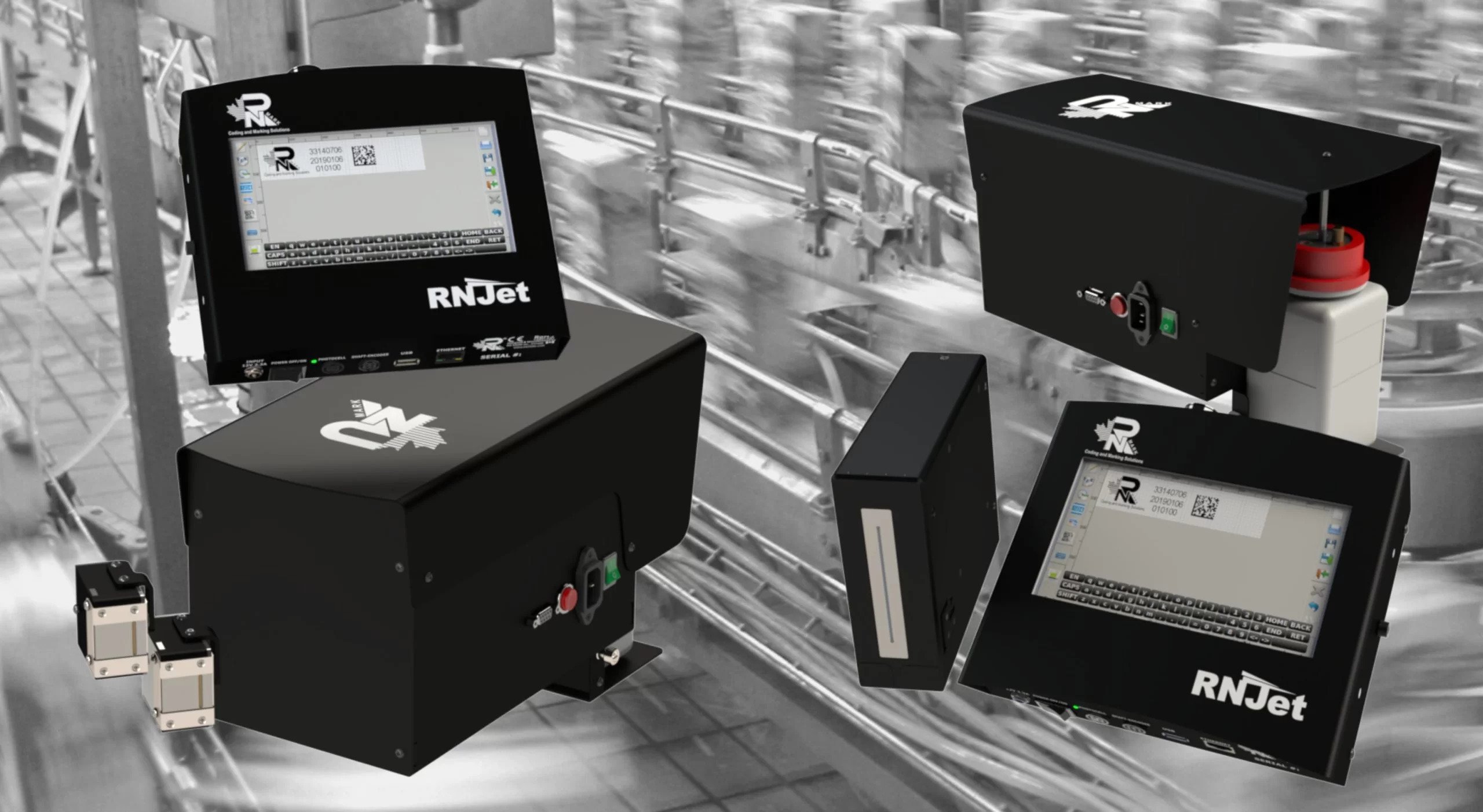

Direct thermal and thermal move barcode units can printing bar signal labels on selection of media. The product range of bar signal units vary from mild work units to durable and high speed commercial units for conference varied requirements. In commercial units, the product range varies from moderate to high quality to extra high quality printers. These units could be integrated to existing applications / ERP for on need label/tag printing.