Aluminum casting is a fascinating and versatile process that allows enthusiasts and beginners to create intricate metal objects with relative ease. Whether you’re interested in crafting jewelry, automotive parts, or artistic sculptures, A356 Aluminum Casting provides a creative outlet with numerous possibilities. In this beginner’s guide, we will explore the fundamentals of aluminum casting techniques, materials, safety precautions, and steps to get you started on your casting journey.

Understanding Aluminum Casting

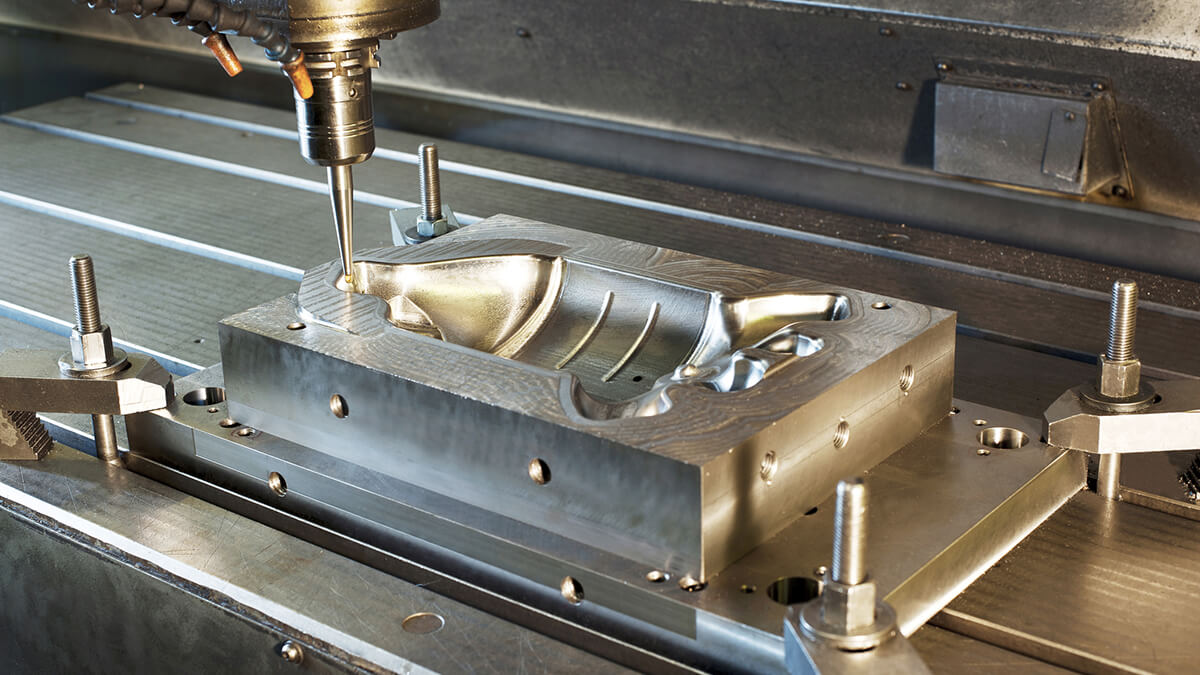

Aluminum casting involves the transformation of aluminum alloys from their molten state into various shapes and forms by pouring the liquid metal into molds. There are two primary methods of aluminum casting that beginners should be aware of:

- Sand Casting: Sand casting is one of the most accessible techniques for beginners. It involves creating a mold using a mixture of sand and a bonding agent. Once the mold is prepared, molten aluminum is poured into the mold cavity, and after cooling and solidifying, the sand mold is broken away to reveal the cast aluminum object.

- Investment Casting: Investment casting, also known as lost-wax casting, is a more intricate but precise method. It is ideal for producing detailed and intricate parts. In this process, a wax pattern of the desired object is coated with a ceramic shell. The wax is melted out, leaving a cavity in the ceramic shell that is filled with molten aluminum.

Materials and Equipment

Before diving into aluminum casting, you will need to gather the necessary materials and equipment. Here’s a list of what you’ll need:

- Aluminum Alloys: Aluminum alloys are available in various compositions, each with distinct properties. Common choices for beginners include A356, 6061, and 7075, which are readily available and relatively easy to work with.

- Furnace: A propane or electric furnace is used to melt the aluminum. You can purchase a furnace or build one if you have the necessary skills.

- Crucible: The crucible is a container that holds the aluminum while it melts. It should be made of heat-resistant material like graphite or ceramic.

- Molds: Depending on your chosen casting method, you will need sand and bonding agents for sand casting or investment casting materials for lost-wax casting.

- Safety Gear: Safety is paramount in aluminum casting. You will need safety equipment like heat-resistant gloves, a face shield, and a heat-resistant apron to protect yourself from molten metal and heat.

- Tongs and Skimmers: These tools are used to handle the crucible and remove impurities from the molten aluminum.

Safety First

Before you start casting aluminum, it’s essential to understand and prioritize safety:

- Protective Gear: Always wear appropriate safety gear, including heat-resistant clothing, gloves, and a face shield.

- Ventilation: Perform casting in a well-ventilated area or use an exhaust fan to remove fumes from the melting aluminum.

- Fire Safety: Have a fire extinguisher on hand and know how to use it. Keep a safe distance from flammable materials.

- First Aid: Know the location of a first-aid kit and have knowledge of basic first-aid procedures.

The Casting Process

Now that you have your materials, equipment, and safety precautions in place, let’s briefly outline the casting process:

- Prepare the Mold: Depending on your chosen method, prepare the sand mold or investment mold according to your design.

- Melt the Aluminum: Load the crucible with aluminum scraps or ingots and place it in the furnace. Heat the aluminum until it becomes molten.

- Pour the Aluminum: Carefully pour the molten aluminum into the mold. Be cautious and precise to avoid accidents.

- Cool and Remove: Allow the aluminum to cool and solidify within the mold. The cooling time varies depending on the size and complexity of the cast. Once cooled, remove the cast from the mold.

- Finishing: Trim, clean, and polish the cast aluminum to achieve the desired final product.

Conclusion

Aluminum casting can be a rewarding hobby for beginners willing to learn and practice the necessary techniques. Start with simple projects to build your skills and gradually take on more complex designs. Remember to prioritize safety at all times, and with dedication and creativity, you can produce impressive aluminum castings that showcase your talent and craftsmanship. Happy casting!